A military airbase in the process of upgrade

In 2011, a decision was made to shut down several aging military airports in Germany to concentrate activities on a few modern facilities. The airbase in Niederstetten escaped closure and was identified for renovation as it is centrally located in the triangle formed by Frankfurt, Stuttgart, and Nuremberg. It was decided that the army facilities would station the recently developed NH90 helicopters. Hall 01 replaced an outdated building and houses helicopter parts and supplies. The structure was built to provide the perfect conditions to store these valuable assets.

Adding ingenuity to simplicity

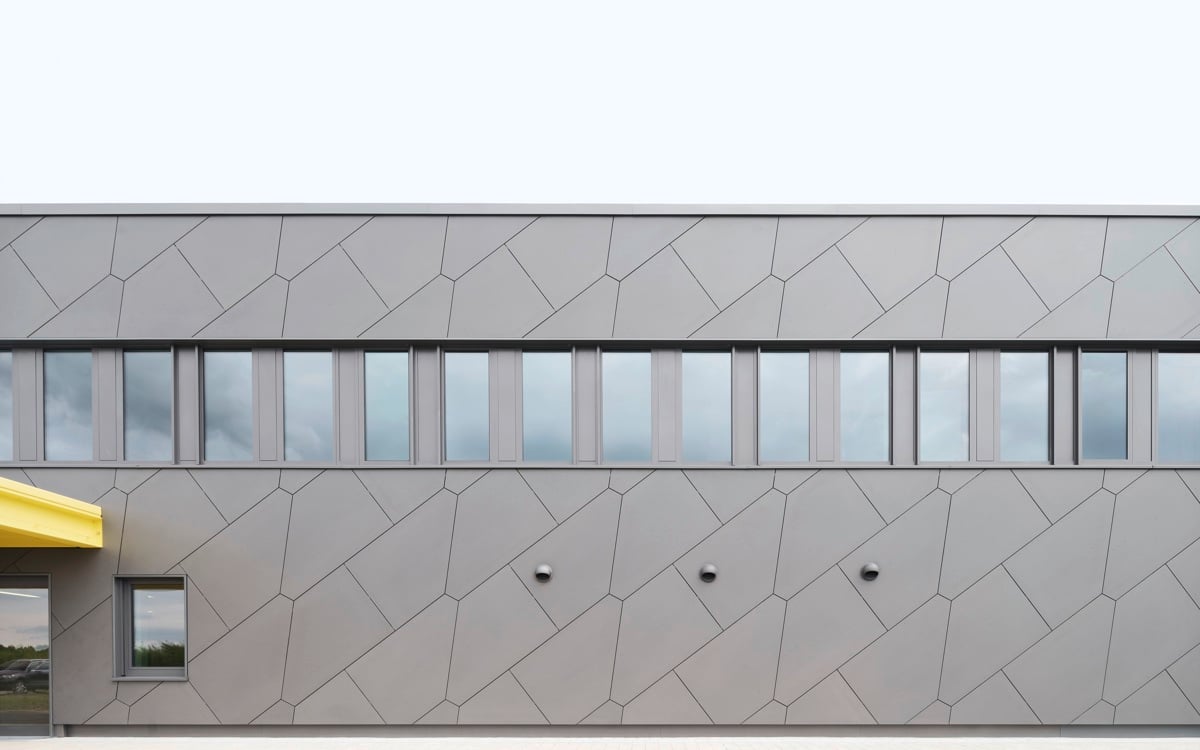

Warehouses that are inaccessible to the public generally do not receive architectural attention, with functional requirements eclipsing aesthetic choices. The specifications for a new supply hall in Niederstetten described a straightforward box building. When Ecker Architects in Heidelberg were chosen to design this building, they took on the challenge to add ingenuity to this simple prismatic volume. Cladding the building with anthracite EQUITONE [natura] panels, cut into simple geometric shapes, the architects eliminated horizontal and vertical joints over the entirety of the gray rainscreen façade, emphasizing its monolithic appearance. The repetitive network of panel joints bring to mind the camouflage nets used by the military. The EQUITONE [natura] panels subtly underscore the rhythm of the raw fiber cement facade, producing an aesthetic of uniformity without monotony. The narrow diagonal joints between panels contribute to an expression of precision. As the joints deliberately continue around the corner, the hall appears more like a minimalistic sculpture rather than a simple industrial warehouse. The monolithic block is interrupted by a solitary entrance dock, faced with white EQUITONE [natura] panels. The large, horizontal facade panels reflect daylight into this space, making a stark contrast to the overall dark gray appearance of the hall.

High-quality material provides optimal conditions

The goods that will be stored in Hall 01 are extremely sensitive, requiring an interior climate with a narrow range of stability. Temperatures should not vary more than 5°C (40°F) and relative humidity fluctuations should be kept to 5% .

The architects chose a ventilated rainscreen cladding system with fiber cement panels allowing air to circulate behind the panels. This application dissipates humidity and decreases the thermal load on the building façade.

To eliminate solar gains there are no skylights or windows in the climatically controlled warehouse. To give the staff an idea of the time of day and the weather conditions, the architects placed a row of narrow skylights along the space leading to offices on the first floor, visible through the ribbon window along this access corridor.

Decomposable facade system with minimal waste

The rear-ventilated rainscreen façade does not only fulfill the required climatic parameters for this building, but it is also a conscious ecological choice.

Fiber cement facade panels are composed of commonly available ingredients that are low in toxicity: cement, mineral raw materials (usually silica sand), a selection of natural and synthetic fibres and water.

In this case, the sustainable EQUITONE facade panels were cut in the desired geometric shape resulting in just 1.6% cut-off waste. The durable cladding protects the building’s structure from the elements, considerably increasing its lifespan. The panels are low maintenance and can be easily replaced in case of damage. Individual panels can be removed to give maintenance teams easy access to the underlying structure. At the end of the building’s life, the entire façade can be removed and for example be reused in another building.

Discover more EQUITONE examples or contact a specialist near you.